When designing inductors for automotive products, one of the most critical steps is selecting the appropriate material.

Recently, a friend from the automotive industry posed an interesting question: “Our custom inductor products involve both ferrite and nanocrystalline core materials. What are the advantages and disadvantages of each, and how should we make the right choice?” Before addressing this, we need to compare the key properties of these two materials in detail.

Comparison of Ferrite and Nanocrystalline Materials

1. Cost and Process Maturity

Ferrite materials have always been the most commonly used inductor material due to their mature manufacturing process and low cost. In many low-frequency applications, ferrite materials are the ideal choice due to their excellent magnetic properties. However, as frequency and temperature requirements rise, the performance of ferrite significantly degrades, especially in high-frequency and high-temperature environments.

In response to the market demand, nanocrystalline materials have emerged as a new alternative. Their high-frequency performance and temperature stability have earned them broad recognition in the industry. However, nanocrystalline materials still need to be perfected in terms of production processes, and their higher cost presents a challenge in cost control.

2. Performance Comparison

When selecting materials, we need to consider several performance indicators. Below is a comparison of the two materials in different aspects:

Magnetic Permeability: Nanocrystalline materials have significantly higher magnetic permeability at high frequencies than ferrite.

Operating Frequency: Ferrite is suitable for low-frequency applications, while nanocrystalline performs better in high-frequency applications.

Saturation Flux Density: Nanocrystalline materials have a much higher saturation flux density than ferrite, making them suitable for high-power applications.

Losses: Nanocrystalline materials have relatively lower losses at high frequencies, making them ideal for high-efficiency applications.

3. Materials Selection in Automotive Applications

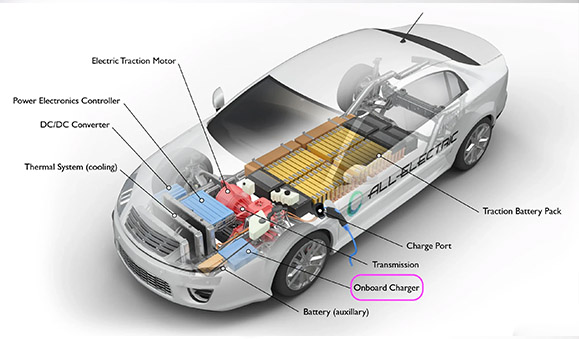

In the current automotive industry, especially in electric vehicles (EV) and energy vehicles, the requirements for inductor materials are becoming increasingly stringent. This is particularly true for high-voltage platforms (800V) and applications using SiC/GaN devices, where the demands for high-frequency performance, efficiency, temperature stability, and electromagnetic interference (EMI) resistance are even more critical.

1. Nanocrystalline Materials Innovation in OBC On-Board Chargers

In On-Board Charger (OBC) systems, nanocrystalline materials, used as resonant inductors in LLC topology circuits, have been proven to significantly improve charger efficiency. As electric vehicle charging technology continues to advance, improving charging efficiency, reducing charging time, and decreasing device size have become industry priorities. In the future, as more high-speed charging standards are adopted, the application of nanocrystalline materials in OBCs will continue to optimize, potentially leading to designs with higher integration and more stable performance. By combining nanocrystalline materials with others like graphene or high-performance ceramics, it is expected that their heat dissipation and stability will further improve, contributing to a faster, more efficient charging experience for electric vehicles.

With the growing adoption of electric vehicles, the demand for charging infrastructure is increasing. In the future, OBC chargers will not only need higher efficiency and smaller size but also intelligent features to accommodate various charging requirements. The progress of nanocrystalline materials will play a more significant role in future EV charging technology, particularly in high-power-density systems and fast-charging applications, which will drive the automotive industry into a more intelligent and convenient era.

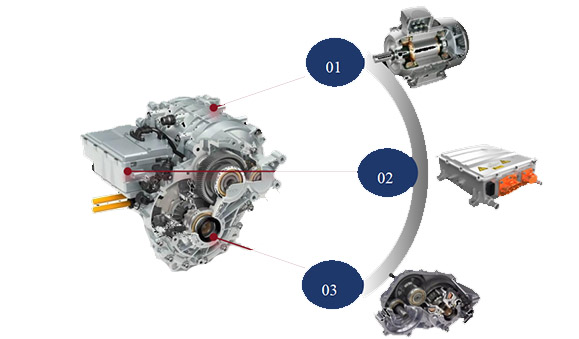

2. Application Prospects of Nanocrystalline Materials in Motor Drive Systems

In electric motor drive systems, the widespread use of nanocrystalline materials is rewriting the design of electric vehicle power systems. They optimize the output filtering of inverters, reduce electromagnetic interference, and effectively suppress total harmonic distortion (THD < 2%), improving the stability of the drive system. As power density and efficiency requirements increase, future electric vehicles will increasingly rely on high-performance inductor materials. In particular, nanocrystalline materials will help achieve more efficient, compact, and stable power transmission in motor drive systems.

As electric vehicle technology continues to develop, motor drive systems will face challenges of higher efficiency, more compact design, and smarter features. Nanocrystalline materials, as key components, will continue to lead innovations in electric vehicle power systems. In the future, with the rise of technologies such as 5G and autonomous driving, the complexity and stability requirements of motor drive systems will continue to increase. The low loss, high-frequency characteristics, and good temperature stability of nanocrystalline materials will make them play an even greater role in high-performance motor drive systems.

3. DC-DC Application on High-Voltage Platforms and Nanocrystalline Material Advantages

For high-voltage platforms of 800V and above, nanocrystalline materials have become the mainstream choice. Their transient response time (less than 5μs) and high-frequency characteristics enable them to quickly respond to current changes, improving system stability and response speed. In future high-voltage platforms, nanocrystalline materials will not only serve as inductive materials but may also integrate with other high-performance semiconductor materials (such as SiC and GaN), driving more efficient and compact power conversion technologies.

As electric vehicles continue to demand high-voltage platforms, particularly for 800V and above systems, the advantages of nanocrystalline materials become more evident. In the future, electric vehicles are likely to adopt more high-voltage systems and ultra-fast charging technologies, which will further push the demand for nanocrystalline materials’ high-frequency response capabilities. Coupled with advanced SiC and GaN semiconductor technologies, the use of nanocrystalline materials will break through the limitations of traditional inductive designs, achieving more efficient and stable power conversion, further optimizing electric vehicle power systems.

4. The Unique Advantages of Ferrite Materials: Irreplaceable in Low-Voltage Conversion

Although nanocrystalline materials excel in high-voltage applications, ferrite materials still maintain a strong competitive edge in low-voltage conversion systems (such as 400V → 24V). Their cost advantages and good low-frequency performance make them the dominant choice for low-power applications. In the future, further optimization of ferrite materials, particularly in terms of reduced losses and enhanced high-temperature performance, will provide more solutions for low-voltage power systems.

While nanocrystalline materials have made significant progress in high-voltage and high-frequency applications, ferrite materials still hold an irreplaceable position in low-voltage and low-frequency applications. Particularly in cost-sensitive applications, ferrite materials’ advantages remain hard to surpass. As material science advances, ferrite materials may combine with other innovative materials (such as composite ferrites or ferrimagnetic ceramics) to further enhance their performance and maintain their dominance in low-voltage conversion systems.

5. Exploring and Developing Environmentally Friendly Materials

As global environmental regulations become stricter, the selection of materials for automotive electronic systems is moving toward greener, more sustainable options. In the future, materials used in on-board chargers, motor drive systems, and power conversion devices will not only need to meet high-performance standards but also adhere to environmental and resource-recycling standards. Future research may focus on developing more environmentally friendly and recyclable magnetic materials to support the sustainable development of the automotive industry.

Environmental friendliness and sustainability have become crucial factors in selecting materials for automotive applications. With the implementation of stricter global environmental regulations, green design for automotive electronic materials will become a key research direction. For instance, in the future, magnetic materials based on renewable resources or highly recyclable composite materials may emerge. These green materials will not only reduce the carbon footprint in the automotive manufacturing process but also provide car owners with a more eco-friendly and safe driving experience.

6. Material Integration and Smart Applications: The Future of Multifunctional Composite Materials

With the growing demand for intelligence and multifunctional integration, materials used in automotive electronic systems are also advancing towards composites and smart materials. In the future, the combined use of nanocrystalline, ferrite, and other new materials will enable inductors to not only fulfill traditional electromagnetic functions but also integrate more intelligent features, such as temperature, humidity sensors, and communication capabilities.

Future automotive inductive components may achieve multifunctional integration, not only optimizing electromagnetic performance but also providing intelligent monitoring and adaptive control functions. For example, composite materials integrated with sensing technologies can monitor the status of electrical systems in real-time and intelligently adjust to optimize power transmission efficiency, or even alert system faults. These intelligent inductive components will greatly enhance the safety, reliability, and long-term maintainability of automotive systems.

Conclusion

Ultimately, the selection of materials depends on specific application requirements, including operating frequency, power demands, size constraints, and cost control. Both ferrite and nanocrystalline materials offer unique benefits depending on the use case.

Recommended articles:

▶How Inductors and High-Frequency Transformers Improve LED Power Supply Efficiency and EMI Performance

▷Why are switching power supplies using high-frequency transformers smaller in size?

▶How the Size of a Low-Frequency Transformer Affects Voltage Output

▷The difference between ferrite beads and inductors

Post time: May-10-2025