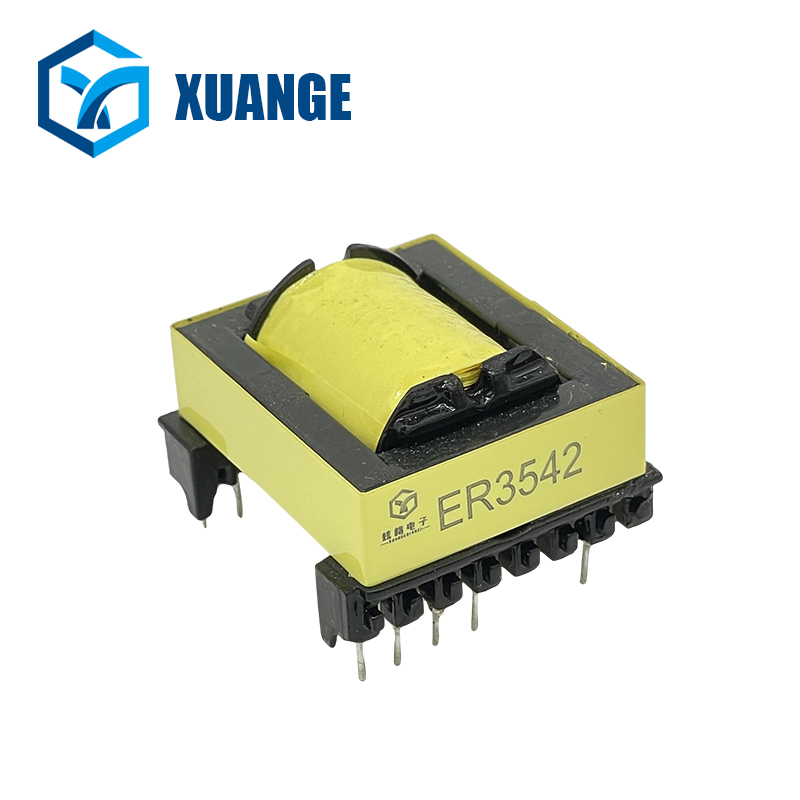

As the leader of Xuange Electronics, a company with 14 years of experience in producing high-frequency transformers and inductors, I am happy to share with you the process of making a step-up transformer. Step-up transformers are essential components in many electrical systems, and our company prides itself on producing environmentally friendly products that are UL listed and certified to ISO9001, ISO14001, and ATF16949.

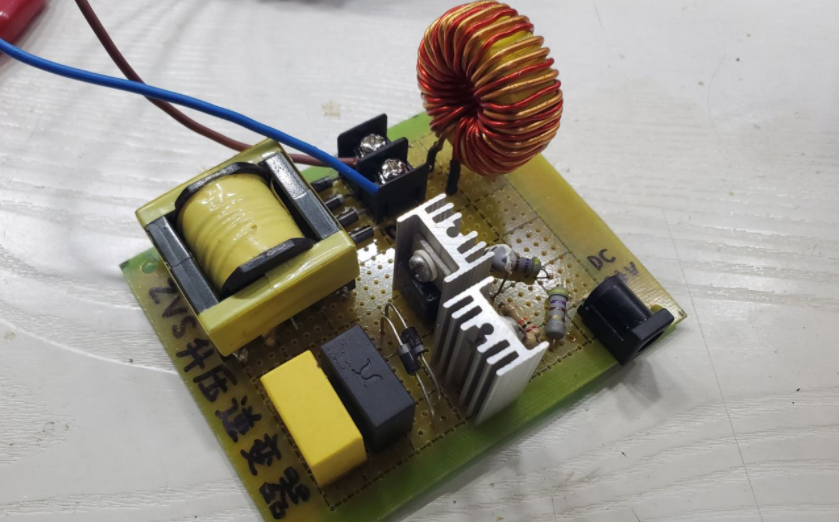

Before I delve into the process of making a step-up transformer, let me first explain what a transformer does in general. A transformer is an electrical device used to transfer electrical energy from one circuit to another through inductively coupled conductors. They can raise (increase) or lower (decrease) the voltage level of an electrical signal. In particular, step-up transformers are designed to increase the voltage from input to output, making them indispensable in a wide range of applications such as consumer power supplies, industrial power supplies, new energy power supplies, and LED power supplies. more.

The process of building a step-up transformer begins with careful planning and design. Xuange Electronics' strong R&D team played a vital role in this initial stage. They work tirelessly to provide solutions that reduce temperature, eliminate noise and ensure proper coupled radiation conductivity. This is essential to ensure that the step-up transformer meets the specifications and standards required for its intended application.

After the design phase is complete, the next step in the manufacturing process is to select the appropriate materials. At Xuenger Electronics, we use only high-quality materials in our production process. This includes careful selection of core materials, which are typically made from materials such as silicon steel or ferrite. The choice of core material is critical as it determines the performance and efficiency of the step-up transformer.

Once the material is selected, the wrapping process begins. This involves winding the primary and secondary coils of the transformer around a magnetic core. The number of turns in each coil and the gauge of wire used are carefully calculated to ensure that the transformer meets the required voltage and current specifications. Our experienced and skilled technicians handle this process with precision and attention to detail.

Once the winding process is complete, the transformer undergoes a series of tests to ensure it meets our high quality standards. This includes testing factors such as insulation resistance, turns ratio and inductance. Make any necessary adjustments at this stage to ensure optimal transformer performance.

At Xuange Electronics, we are proud to produce high-quality step-up transformers, which are widely used in new energy, photovoltaic, UPS, robotics, smart home, security systems, medical and communications fields. Our commitment to producing environmentally friendly products that meet the highest quality and safety standards sets us apart in the industry.

In summary, the step-up transformer manufacturing process requires careful planning, precise design and material selection, skilled winding techniques, and thorough testing and inspection. At Xuange Electronics, we are committed to producing transformers and inductors that meet the diverse needs of customers in various industries. Our high frequency transformers and inductors demonstrate our commitment to excellence and innovation in electrical engineering.